19.07.2023

Commentary

Carbon emissions tracking and how coupling with material traceability satisfies current and future needs for sustainable products

A growing number of global regulations require calculations of the carbon emissions across entire supply chains, as well as the attribution of these emissions to individual products.

Both companies and regulators increasingly realize that meeting their emissions goals requires tackling emissions further upstream—the activities inherited by OEMs and downstream customers from their supply chains. In fact, for downstream customers, these inherited emissions account for 80% of their emissions overall.

The first-movers regulations that require such proof of embedded carbon emissions largely affect transportation, raw materials, and energy industries, and include the EU Carbon Border Adjustment Mechanism (CBAM), EU Emissions Trading System (ETS), the EU Ecodesign for Sustainable Products Regulation (ESPR) and the now final EU Battery Regulation.

The EU Battery Regulation was approved by the European Council on July 10th and applies to all light means of transport batteries, industrial batteries above 2 kWh, and electric vehicle batteries placed on the European market.

Companies will need to provide carbon footprint declarations for all batteries by Q1 2025, classify such batteries into performance classes by Q3 2026, and prove that the life cycle carbon footprint falls below certain thresholds by Q1 2028. Furthermore, the regulation’s battery passport requirement necessitates carbon footprint declarations differentiated per life cycle stage, to be made publicly available by Q1 2027. To ensure a standardized approach, the European Commission is expected to finalize its Carbon Footprint methodology for batteries, based on the latest version of the Product Environmental Footprint (PEF) methodology and its relevant Category Rules (PEFCRs), by Q1 2024.

A similar approach is expected with the forthcoming ESPR and its requirements for carbon performance thresholds and digital product passports. For CBAM and ETS, even greater levels of information on emissions will be required to prevent carbon leakage and prove that products themselves—based on their incurred emissions throughout production—are compliant in accessing the European marketplace.

What is the best way to approach this?

When it comes to reducing carbon emissions, it is clear that supply chains need to be fully understood—end-to-end. The more visibility, the more control. A comprehensive and transparent approach to trace the entire lifecycle of materials is needed to enable accurate carbon footprint calculations that use primary data based on the actual flow of materials, and include accurate data on electricity usage, from the entire supply chain.

By tracking the entire lifecycle of materials in this way, companies can identify emission hotspots, compare products between suppliers, and implement targeted reduction strategies to deliver business value around decarbonization, while also creating the proof they need to showcase sustainability efforts to regulators and consumers.

How to get started with emissions tracking

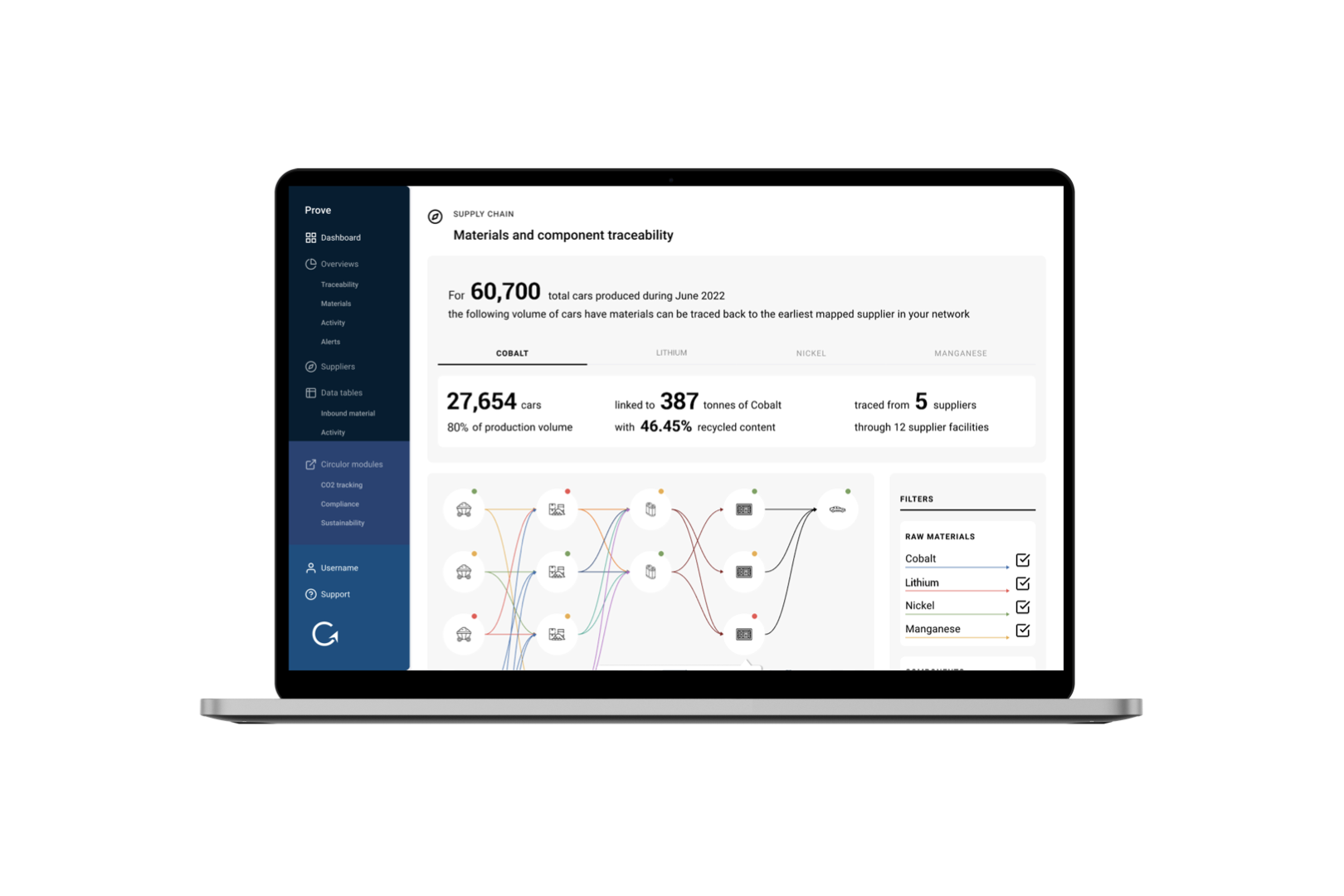

Circulor’s innovative emissions tracking platform provides a holistic and comprehensive view of your products and organization’s carbon footprint—with actionable insights. Built on the foundation of material traceability, our clients track carbon emissions based on the actual flow of materials, as opposed to static, point-in-time, estimates.

By capturing and validating emissions data at each step of production, Circulor dynamically aggregates emissions across the supply chain so that customers gain a detailed and up-to-date view of both their own and their inherited emissions.

Source: Circulor’s PROVE platform and carbon emissions dashboard, showing the breakdown of Scope 1, 2 and 3 from upstream emissions based on the flow of materials for a battery module.

Circulor supports the collaboration with suppliers to collect and share the necessary data related to your supply chains and carbon emissions including energy usage, transportation, and raw materials. Working across supply chain tiers makes a transformational difference and encourages every supplier to take responsibility to measure their activity and share the requirements with the next.

Polestar, who partnered with Circulor in May 2021 to build a carbon-neutral car by 2030 (the Polestar 0), recently announced an 8% reduction in relative CO₂ emissions per car produced in their 2023 Sustainability Report. This is on top of a further 6% emissions reduction per car produced announced in their 2022 report, specifically citing the partnership with Circulor as a key enabler to this.

To Summarize

Given the global trend toward supply chain transparency, stricter emissions regulations, and the preference for primary data in verifying carbon reduction claims, material traceability is critical. It is expected that more stringent measures, like that of the EU Battery Regulation, will be incorporated in future regulations.

Circulor's approach to carbon tracking involves dynamically attributing emissions from direct operations and supply chain participants based on material flow. This enables organizations to make informed decisions, achieve their goals, and enhance environmental accountability beyond regulatory requirements. By providing end-to-end visibility, Circulor customers identify and address emissions hotspots more effectively, create data-based collaboration among their upstream suppliers, and become standard bearers in greater responsibility.

![Acculon RA Circulor - website image.001[44].png](/_next/image?url=https%3A%2F%2Fdecisive-wonder-fa24533282.media.strapiapp.com%2FAcculon_RA_Circulor_website_image_001_44_2720fb315d.png&w=1920&q=75)