11.10.2023

Commentary

How Circulor's scale and market-leading solutions bring a network effect to our customers

As the world’s collective environmental consciousness grows, battery value chain participants face increasing requirements to prove the responsibility and sustainability of their products, while also needing to secure a reliable and resilient supply of the critical minerals to produce them.

This is certainly a challenge, but much of the answer can be found in establishing supply chain transparency – especially in relation to fulfilling the needs of the EU Battery Regulation and the U.S. Inflation Reduction Act’s Clean Vehicle Tax Credit. Companies need verifiable proof of material provenance and the production journey, along with inherited CO₂-e emissions, proof of compliant sourcing, recycled content quotas, and collection targets as batteries reach end-of-life. This is certainly no small task, but Circulor is here to help.

Largest network of EV battery value chain participants

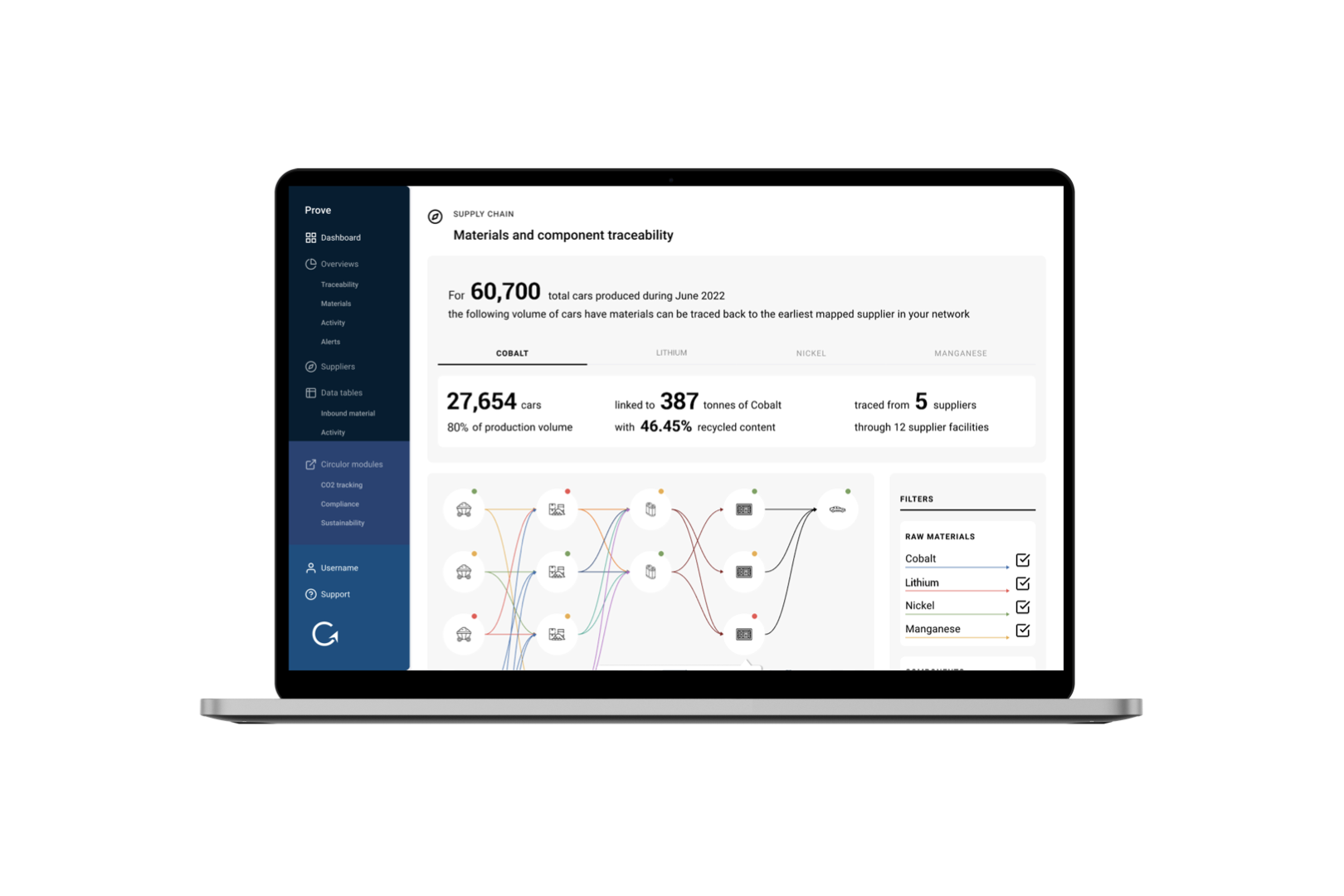

As the most mature and complete supply chain traceability solution available today, Circulor is able to respond to these growing needs. Our technology platform, PROVE, is built for companies and their supply chains to provide visibility and proof of the activity at all stages in the production process. We do this by tracking the flow of physical materials as they change chemical and physical state from raw to final product, with traceability enabled at every production step to create a reliable digital chain of custody.

Already used at scale by globally recognized brands, PROVE has the largest battery traceability network on the market, with over 145 customer facilities connected globally and actively contributing traceability and sustainability data. We work with 52% of global cell manufacturing capacity (by production volume) and have provided supply chain visibility for over 157 million battery cells in 670,000 EVs by collecting over 2.5 billion traceability data points.

The word Circulor is derived from the Latin word meaning ‘to form groups’, and enabling a network effect is an important way we drive value for our customers. As we begin working with new clients, we map their supply chains and onboard their suppliers to gather traceability and sustainability data to our platform.

This ongoing expansion of our network continuously benefits new and future customers, since it means that many of their suppliers are likely to be already connected on our platform for specific materials, components or products - so we already have established relationships with them and they have many of the systems and processes in place to provide the data required, making the implementation process increasingly efficient and straightforward.

Supply chain traceability with Circulor

We already work at scale with numerous OEMs in their EV battery supply chains, including Volvo Cars, Polestar, Volkswagen, Daimler, and BMW – and the list is only growing.

Our PROVE platform is modular and flexible, enabling easy starting points for supply chain mapping, material traceability, emissions tracking, compliance, sustainability, and digital product passports.

Together, we tailor this full suite of applications as required to suit a customer’s supply chain transparency needs over certain milestones and timelines by which they need to achieve their goals.

![Acculon RA Circulor - website image.001[44].png](/_next/image?url=https%3A%2F%2Fdecisive-wonder-fa24533282.media.strapiapp.com%2FAcculon_RA_Circulor_website_image_001_44_2720fb315d.png&w=1920&q=75)