31.07.2024

News

July 2024 Newsletter: Recycling and digital proof: Circularity coming to life

Benchmark Minerals Intelligence reports waste recycling services grew a record 6.3% from 2023 to 2024 to $62.22B and looks poised to reach $78.43B by 2028. Benchmark attributes this growth to several reasons, including greater awareness of environmental sustainability, advancements in regulatory pressure, and more ubiquitous adoption of circular economy practices.

This is positive news. For example, with ever-increasing numbers of used batteries on the market—from portable electronics to electric vehicles and industrial applications—recycling volumes are growing steadily to spur business opportunity.

However, the circular economy requires transparency, particularly to measure purity levels, know exact percentages of recycled content within products, and ensure products are less carbon intensive than their virgin counterparts.

These data points are also key when satisfying specific regulations. The EU Battery Regulation sets increasingly stringent targets for economic operators—those placing the battery on the market—who must prove increasing volumes of recycled cobalt, lithium and nickel by August 2028 and incorporate such information into a battery’s Battery Passport. And let’s not forget the recyclers, who must report recycling rates of various extracted materials and measure the efficiency of their recycling processes.

Additionally, a key aspect of the EU’s Critical Raw Materials Act is to improve the circularity of critical raw materials and enhance recycling processes across the bloc, including a benchmark that 25% of the EU’s annual consumption of strategic raw materials comes from domestic recycling capacity by 2030. This theme continues. Earlier this month, in its announcement of the new Circular Economy Act, it became abundantly clear that spurring demand for secondary materials is a top priority for the next European Commission, especially to create a circular European economy.

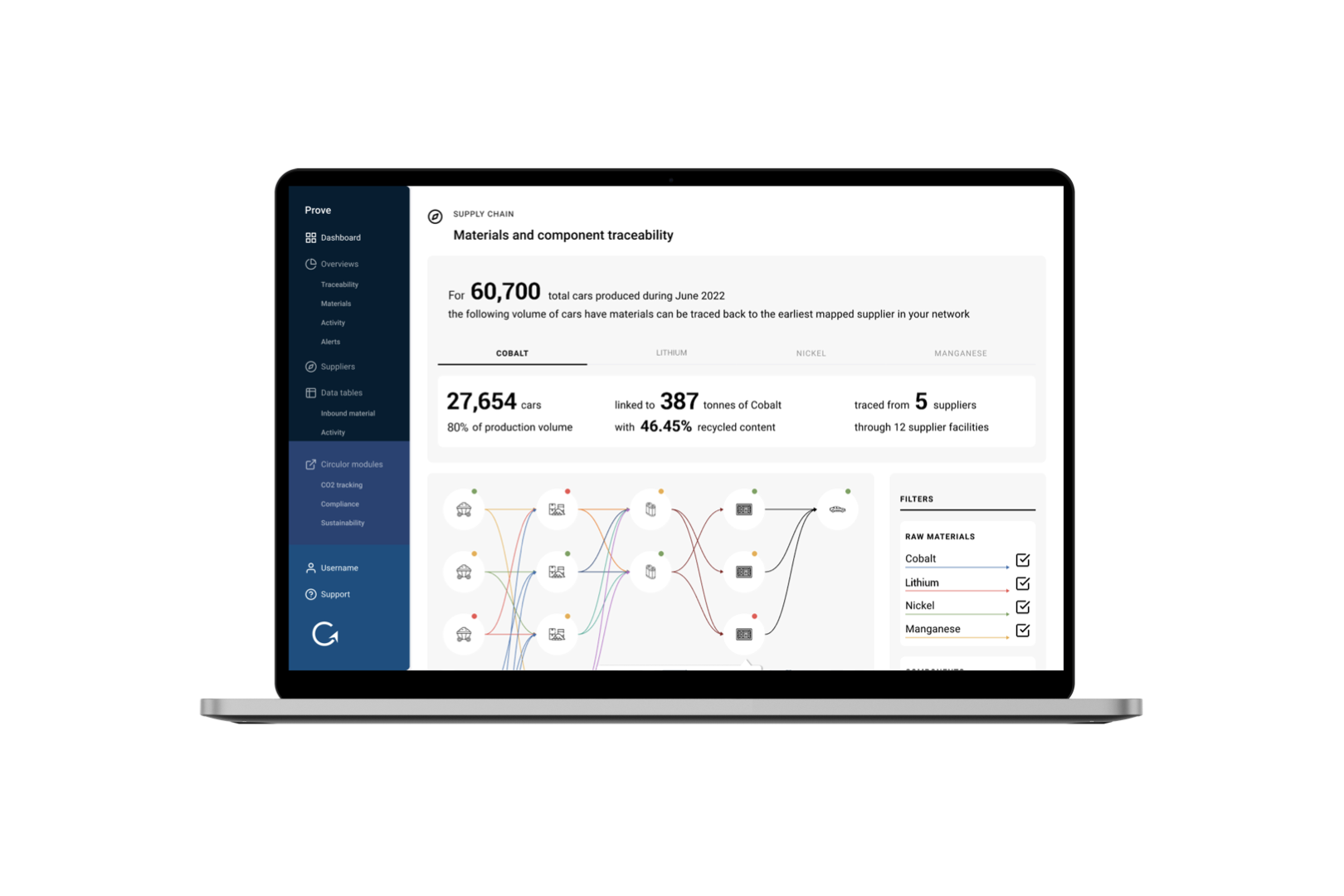

Circularity is no longer theoretical or futuristic. It’s tangible business and market opportunity with digital solutions like Circulor’s accelerating the maturation. This step-by-step demonstration of the Circulor PROVE platform showcases how recycled content and its origin, material journey, and embedded emissions are traced and evidenced. This is circularity coming to life.

We look forward to continuing to bring you these global insights here, on circulor.com and LinkedIn. More on the latest global traceability trends below.

What we’re reading

Driving towards Green Steel in Europe

Transport & Environment reports that the auto industry could lead Europe's low-carbon steel production. The think tank suggests that via the EU End-of life Vehicles regulation, which is currently being revised by lawmakers, at least 40% of steel in new cars should be green by 2030, rising to 75% in 2035 and 100% in 2040. Using green hydrogen and electric arc furnace steel, or recycled scrap steel, could cut car production CO2 emissions significantly by 2030. Notably, transitioning to 100% green steel by 2040 would add only €8 more to the steel manufacturing cost of the vehicle.

ESPR enters into force

The Ecodesign for Sustainable Products Regulation (ESPR), which came into force on July 18, 2024, is a pivotal part of the European Commission’s strategy to promote environmentally sustainable and circular products, foster sustainable business models and strengthen the EU economy’s competitiveness and resilience. New measures include a timeline for industry adoption of Digital Product Passports (DPPs) for products such as steel, aluminum, electronics and textiles. Learn more on implementing DPPs here.

New US initiative to improve battery recycling

The U.S. Department of Energy has announced $14M to establish over 1,000 battery collection sites, as part of a $62M initiative to improve battery recycling. Via WIRED, this effort addresses environmental, economic, and safety concerns, as improper disposal of lithium-ion batteries can lead to toxic leaks and loss of critical materials needed for clean energy technologies.

The potential for green nickel premiums

Reuters reports that even though nickel produced with higher environmental and social standards should command a premium, it currently doesn’t. Lower prices have trumped responsibility and sustainability, and the challenge is intensified by a lack of transparency, with Benchmark Mineral Intelligence estimating in their green price assessments, that less than a third of global nickel is produced by operators committed to ESG transparency. However, with the EU Battery Passport in 2027 requiring detailed information on carbon footprint, environmental impact and full supply-chain transparency, battery makers and carmakers must move quickly to prepare and mitigate reputational risk.

The ‘Green Bond’ boom

Bond investors are financing the green transition at record rates, crucial for meeting the United Nation’s $3T annual investment goal for the Paris Agreement, as reported by Axios. Green bond issuance hit new highs this year, with over $1T issued since 2021. European investors lead, but issuers are global, with most G7 countries participating.

What we’re sharing

Talon Metals and Circulor partner to track responsibly sourced, domestic nickel

Circulor’s partnership with Talon Metals Corp. will provide Talon’s customers with transparency of upstream production and proof that their operations uphold the highest possible standards for labor rights, environmental protection, and indigenous participation. Using Circulor’s solution to trace minerals produced with high standards means Talon can ensure their mineral sourcing aligns with ESG commitments and regulations such as the EU’s Battery Regulation, ESPR, and CBAM. Read more.

Circulor becomes Global Innovator at the World Economic Forum

Circulor is proud to be recognized as a World Economic Forum Global Innovator for its impact and progress in improving supply chain transparency and sustainability. Global Innovators are the world’s most promising growth-stage companies at the forefront of disruption and innovation in their industries, and Circulor looks forward to both learning from and contributing to the global network and Forum dialogues to continue driving positive, systemic change that shapes our shared futures. Read more.

See for yourself: Circulor’s traceability solution in action

Circulor’s traceability solution ensures the circularity of batteries by tracking their entire lifecycle, from raw material sourcing to recycling. This allows manufacturers to verify the origins and responsible sourcing of materials. A demo of Circulor’s PROVE platform illustrates the tracking of both virgin and recycled materials, monitoring volumes through the supply chain, closed-loop recycling from OEM to Recycler and more. Watch it here.

Due diligence requires traceability

Meeting the EU Battery Regulation's due diligence requirements by August 2025 requires traceability for cobalt, natural graphite, lithium, and nickel. This ensures transparency of critical minerals in batteries amidst geopolitical and economic risks. Circulor’s Material Traceability solution offers fast, verifiable proof of compliance, aiding manufacturers in meeting these regulatory standards efficiently. Read more.

Copper decarbonization and the role of recycling

Copper is crucial for decarbonization technologies yet contributes 0.2% to global GHG emissions. Christina Iosifidou from Siemens Energy highlights the need for supply chain transparency to drive decarbonization. Siemens Energy, in partnership with Ørsted, Siemens Gamesa, and Circulor, is pioneering copper traceability in wind turbine transformers, setting a new standard for transparency and sustainability in renewable energy. Read more.

![Acculon RA Circulor - website image.001[44].png](/_next/image?url=https%3A%2F%2Fdecisive-wonder-fa24533282.media.strapiapp.com%2FAcculon_RA_Circulor_website_image_001_44_2720fb315d.png&w=1920&q=75)