29.05.2024

News

May 2024 Newsletter: Growing global opportunity to harmonize traceability standards

TRACE aims to enhance transparency and reporting mechanisms through the adoption of digital identifiers—i.e. battery passports, as we like to call them in Europe—which provide immutable records of provenance, activity, and compliance across supply chains in near real-time.

A marked departure from traditional methods and static data, “digital battery identifiers and reporting standards would allow for smooth transfer of relevant information between various stakeholders including mining companies, manufacturers, recyclers, consumers, and regulators, while helping meet long-term goals for stable, secure and ethical value chains,” said the bill’s co-sponsor Congressman Paul Tonko (NY-20).

The timing of the TRACE Act is opportune. U.S. Treasury and Energy Departments have recently released final requirements for the Clean Vehicle Tax Credit, Section 30D of Inflation Reduction Act, that affords up to $7,500 off an electric vehicle when the EV’s battery, and its components and critical minerals, are proven to be produced in certain regions.

The tax credit requires qualified manufacturers to comply with global standards of tracing, such as those being implemented for the EU Battery Regulation, and to physically track materials though extraction, processing, manufacturing and assembly to establish reasonable certainty that batteries and their respective electric vehicles are in fact in compliance.

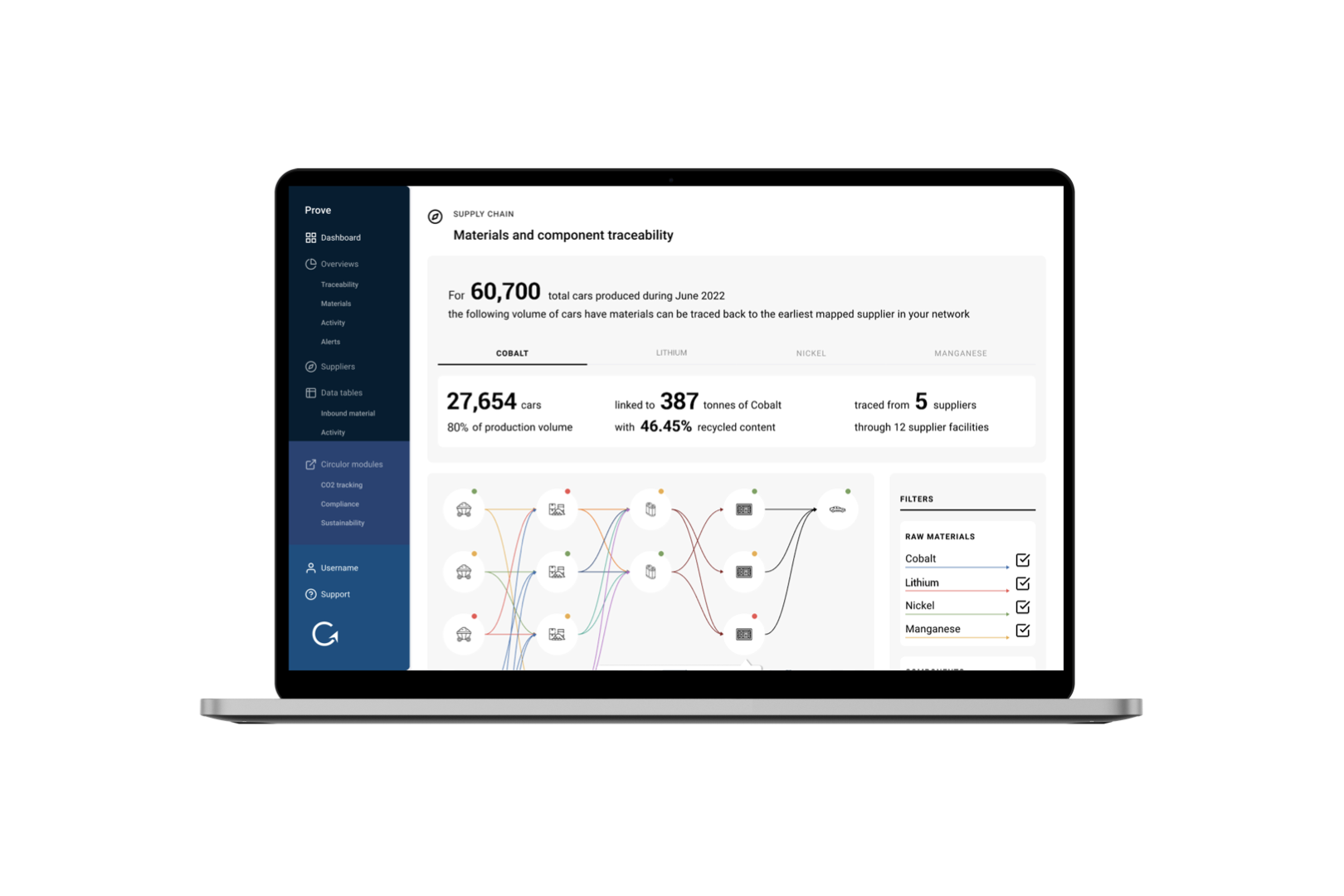

With robust, continuous documentation required by the IRS, along with growing models and volumes, the only way to develop a system of efficiency in responding and adhering to such requirements is to use a supply chain tracing technology and network, such as Circulor.

The U.S. continues to call for progress on supply chain traceability, and as part of TRACE, the Department of Energy is to ensure compatibility with existing standards and laws. That’s increasing synergy not only with the EU, but also Canada, India, Australia, Japan and more who are clearly pursuing the solution of “digital identifiers”.

Check out our latest on TRACE and global dynamics at play here.

We look forward to continuing to bring you these global insights here, as well as on circulor.com and LinkedIn. More on the latest global traceability trends below.

What we're reading...

Microsoft’s clean energy commitments extend to supply chain

Microsoft continues to lead in corporate sustainability by now announcing that its main suppliers will need to use 100% carbon-free electricity for goods and services by 2030. This decision comes after Microsoft’s emissions increased by nearly 30% since 2020, primarily due to AI development. Despite this challenge, the company remains committed to its ambitious goal of becoming carbon negative by 2030.

Why tracking emissions in the fashion industry is so challenging

In a world increasingly focused on sustainability, fashion brands continue to face scrutiny for their environmental impact. Bloomberg reports that assessing these brands’ emission reduction efforts is nothing close to straightforward, especially due to supply chain complexities, “greenwashing,” and growing pressures to adopt circular economy models, reduce waste, and prioritize renewable energy.

Fast growing critical minerals market remains turbulent

The IEA Global Critical Minerals Outlook 2024 highlights the turbulence within the critical minerals market, with prices falling sharply in 2023 after two years of dramatic increases. In terms of ESG performance, sustainability standards can help, but to realize their full potential, greater transparency, thorough due diligence, harmonized credibility approaches, and appropriate incentives are needed.

Navigating the battery cell component opportunity in Europe and North America

The automotive industry is at a crossroads according to McKinsey & Company, facing both challenges and opportunities. In a rapidly changing landscape, factors like geopolitical risks and economic headwinds play a significant role. However, long-term shifts toward electric vehicles (EVs) and digitization are reshaping the industry.

Advancing sustainable battery recycling

The exponential growth in battery demand, coupled with the need for safe and sustainable management of spent batteries, has brought battery recycling into the spotlight. As we strive to reduce our dependence on primary mining and minimize environmental impact, the concept of a circular battery system gains prominence. This whitepaper on “Advancing Sustainable Battery Recycling” from Minviro shares more.

What we're sharing...

New TRACE Act enhances supply chain transparency

Circulor’s latest blog reflects on the introduction of the bipartisan Critical Material Transparency and Reporting of Advanced Clean Energy (TRACE) Act. This legislation aims to establish a traceability program at the U.S. Department of Energy, developing software for digital identifiers and interoperability standards to improve visibility in clean energy supply chains, including batteries. Read more.

What will sustain the push for EV battery traceability?

In a recent interview with Automotive World, Circulor’s CEO Doug Johnson-Poensgen unpacks the need for automakers to prove responsible sourcing to maintain sales in the U.S. and EU, requiring accurate and verifiable traceability data along with close supplier engagement. Read more.

Circulor’s approach to ensuring responsible manufacturing

To ensure materials in products are manufactured responsibly, both material traceability and third-party audits are essential. Circulor’s end-to-end traceability system tracks upstream supply chain activities and integrates third-party audits to continuously monitor supplier performance, offering comprehensive transparency, revolutionizing responsible sourcing for customers, investors, and regulators. Circulor's collaboration with SQM and Volvo Cars exemplifies this approach. Read more.

Circulor solutions bring a network effect to our customers

The battery value chain is increasingly required to demonstrate the responsibility and sustainability of its products on a global scale. Circulor, with the most advanced supply chain traceability solution available today, is at the forefront of helping customers meet these demands. Our extensive network, covering 52% of global cell manufacturing capacity, continues to expand, providing significant advantages to both current and future customers, with many suppliers already connected to our platform. Read more.

![Acculon RA Circulor - website image.001[44].png](/_next/image?url=https%3A%2F%2Fdecisive-wonder-fa24533282.media.strapiapp.com%2FAcculon_RA_Circulor_website_image_001_44_2720fb315d.png&w=1920&q=75)