16.03.2022

Press Releases

Circulor partners with Rock Tech Lithium to provide supply chain provenance and emissions traceability for Europe’s first lithium refinery

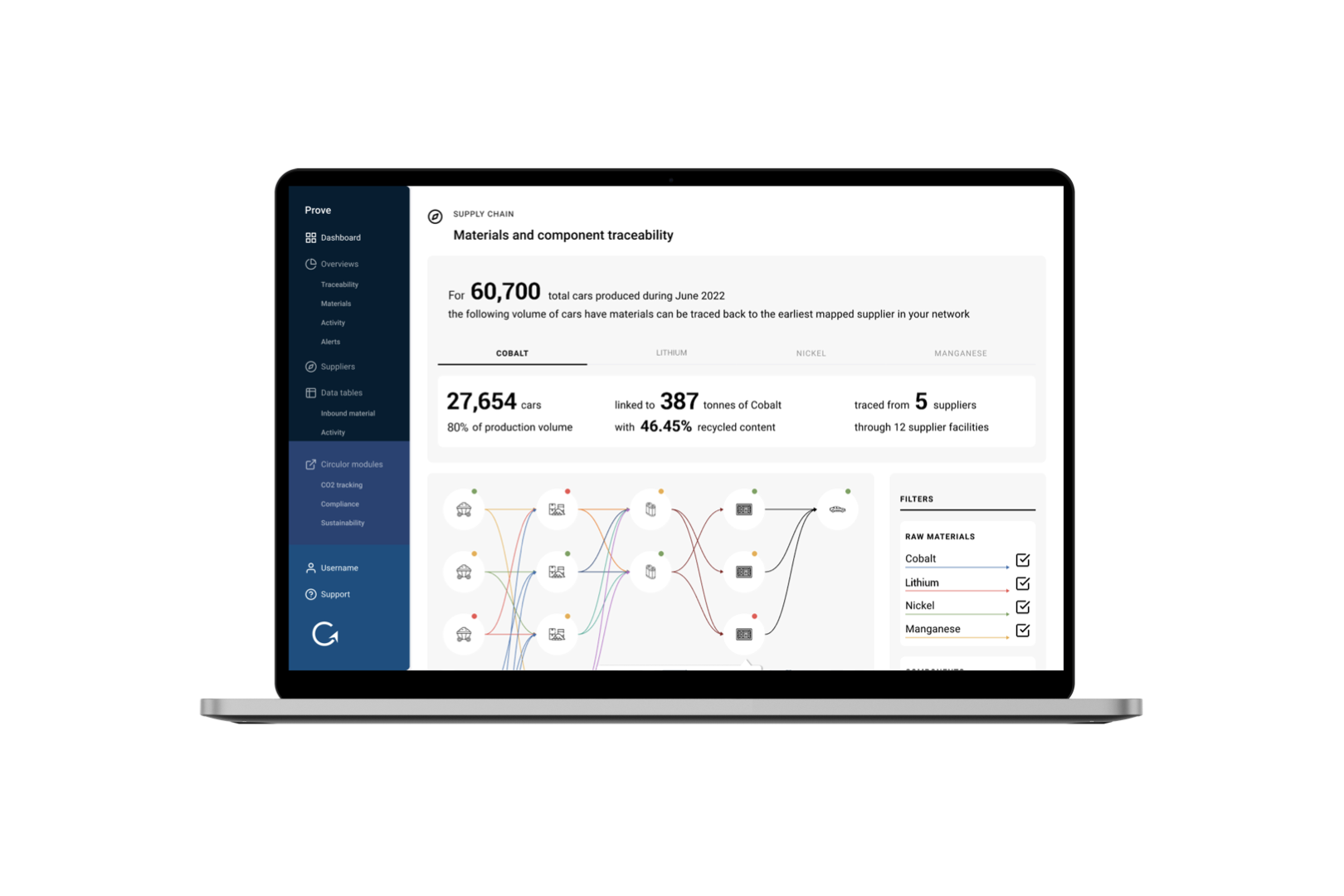

Circulor, the leading sustainable supply chain traceability provider, today announces a comprehensive partnership with Rock Tech Lithium, the Canadian-German cleantech company, and Fraunhofer UMSICHT, an institute of the Fraunhofer-Gesellschaft, the world’s leading applied research organization, to ensure the production of German-made lithium hydroxide with the lowest possible environmental impact.

London-headquartered Circulor will ensure traceability and dynamic CO₂ tracking for Rock Tech’s plant in Brandenburg, which is expected to produce 24,000 metric tons of lithium hydroxide a year – enough for the batteries of half a million electric vehicles. Circulor’s work will precede the EU’s battery regulation, which takes effect as early as 2024.

Douglas Johnson-Poensgen, Circulor CEO, states: "A sustainable and resilient raw material supply chain is increasingly important to our automotive customers, and we are proud to work with Rock Tech to deliver their product with clear proof of origin and embedded CO₂ emissions. As the automotive industry prepares for the EU Battery Directive and battery passport provisions, we're very pleased to support Rock Tech in pioneering low-carbon, European-produced lithium hydroxide."

With the holistic documentation of our value chain, we create a decisive added value for our customers. Customers have information about the origin and life cycle assessment of our lithium hydroxide at all times. Based on the work of Circulor and Fraunhofer UMSICHT, Rock Tech will create a material passport for its product.

Dirk Harbecke, Rock Tech Lithium CEO

Dr. Ilka Gehrke, Head of Environment and Resources Department at Fraunhofer UMSICHT, adds: "Fraunhofer UMSICHT will carry out the life cycle assessment (LCA) of Rock Tech’s production processes. Extensive collection and analysis of their data not only allows Rock Tech to make the production of lithium hydroxide more sustainable, but also supports them in implementing subsequent process optimizations in the most energy and environmentally friendly way possible."

The Rock Tech and Circulor partnership also entails traceability and CO₂ tracking for Rock Tech’s planned recycling at the facility, aiming to become Europe’s first closed-loop supplier of lithium hydroxide. Currently, only one percent of lithium from batteries is recycled worldwide. By 2030, Rock Tech Lithium aims to achieve 50 percent of its materials to come from recycled batteries.

![Acculon RA Circulor - website image.001[44].png](/_next/image?url=https%3A%2F%2Fdecisive-wonder-fa24533282.media.strapiapp.com%2FAcculon_RA_Circulor_website_image_001_44_2720fb315d.png&w=1920&q=75)