21.02.2024

Commentary

Why start your Material Traceability journey now?

As markets focus on building greater economic, geopolitical, and climate resilience, regulatory bodies around the world are introducing measures to ensure that critical industries are growing sustainably, responsibly, and with increasingly domestic, allied, and circular sourcing.

Some such regulations, to name a few, include the EU Battery Regulation and the EU Ecodesign for Sustainable Products Regulation, as well as the U.S. Clean Vehicle Tax Credit.

While these regulations may not be fully effective immediately, manufacturers can reap numerous benefits by proactively preparing and implementing changes in order to meet the deadlines.

Here is what manufacturers and their supply chain participants can gain in starting their material traceability journeys now:

- Preparation Time: Comprehensive supply chain changes cannot be achieved overnight. Manufacturers require time to plan, implement, and adjust. Beginning material traceability activities early ensures a smooth transition to a new system without hasty disruptions that can negatively impact productivity and profitability

- Supplier Collaboration and Evaluation: Meeting new regulatory requirements prompts manufacturers to evaluate suppliers and engage with new partners. If a manufacturer needs to change suppliers, doing so can take time given existing supplier contracts. The sooner they start, the better positioned they will be in fulfilling compliance or proving qualifications for federal incentives.

- Competitive Advantage: Early adoption of responsible and sustainable practices can differentiate a company from its competitors. Consumers and investors are increasingly concerned about environmental and social issues, and companies that can demonstrate their commitment to these areas—especially with product-level proof—can attract increased marketing potential, business opportunity, and investment.

- Risk Management: In deploying supply chain traceability, companies gain visibility into their inherited risks. In addition to regulatory compliance, such insights into upstream supply chain production help companies proactively manage risks, mitigate disruptions, maintain customer satisfaction, and protect brand reputation.

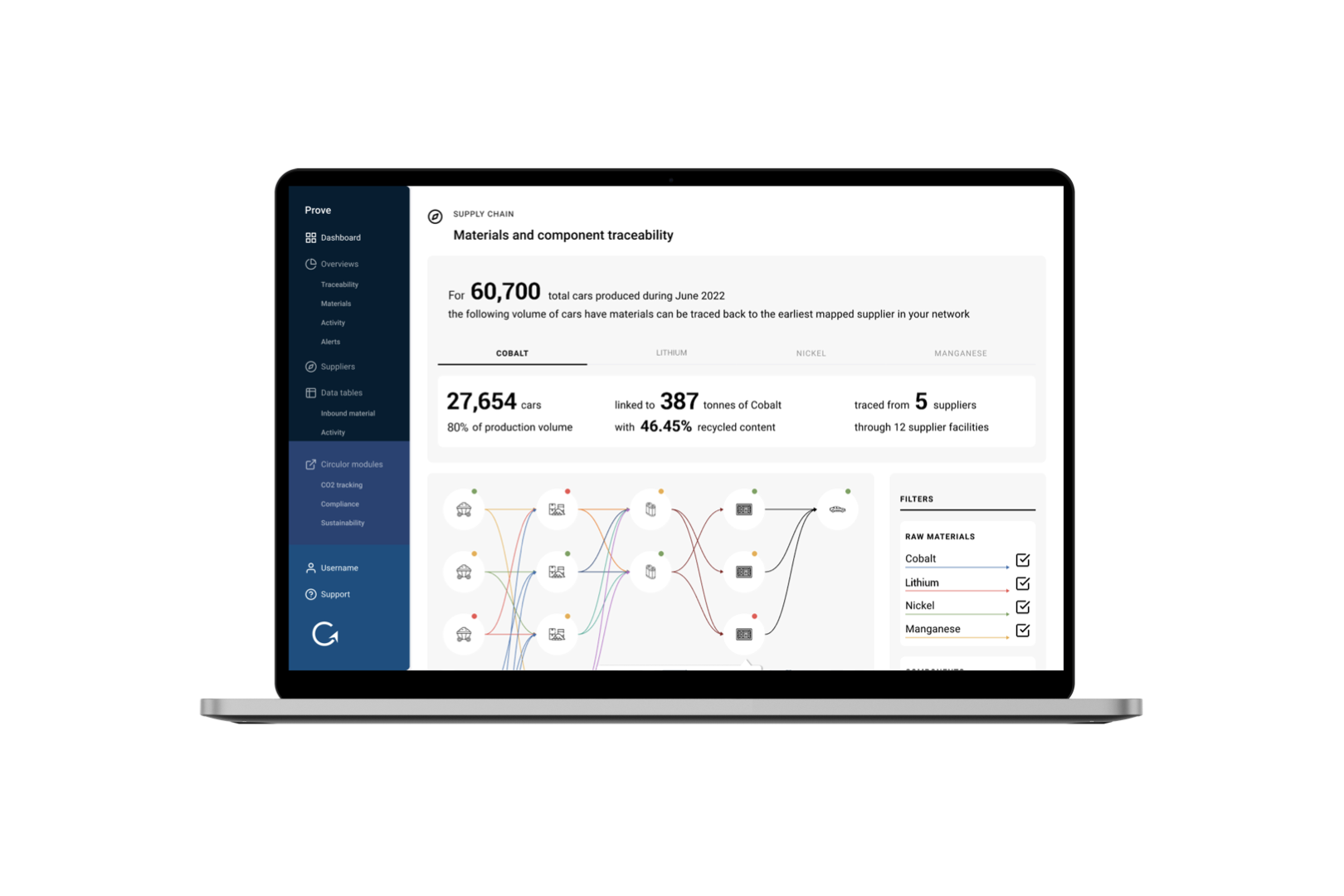

- Technological Adaptation: Learning and adapting company systems to a new technology takes time. By initiating material traceability technologies early, manufacturers can optimize for the benefits, streamlining operations, reducing costs, and improving overall efficiency.

- Future-proofing the Business: Considering the global trend towards stricter environmental regulations, it is likely that more stringent measures will be implemented in the future. By taking proactive steps today, manufacturers can position themselves ahead of the curve and adapt to the evolving landscape, ensuring long-term sustainability and resilience.

- Influence and Leadership: Companies that move early can play a pivotal role in shaping industry standards and regulations. By taking the lead in sourcing practices, manufacturers can influence the direction of the industry, inspire others to follow suit, and become recognized as leaders in social responsibility.

Although global regulations don’t take full effect for a few years, elements have started to be phased in meaning organizations stand to benefit by embracing change ahead of time. In taking proactive steps, they can position themselves for success in a future that increasingly requires proof of where and how upstream production took place.

Early adoption not only offers a competitive advantage but also enables manufacturers to influence industry standards and raise their leadership profile. By prioritizing supply chain visibility and material traceability, these companies can navigate the evolving regulatory landscape with confidence and work toward a more resilient future.

![Acculon RA Circulor - website image.001[44].png](/_next/image?url=https%3A%2F%2Fdecisive-wonder-fa24533282.media.strapiapp.com%2FAcculon_RA_Circulor_website_image_001_44_2720fb315d.png&w=1920&q=75)